High Precision Machining

Jim has been – and is – a great supplier to us for machining and expertise. Extremely flexible and responsive. I would highly recommend Lenane Precision for any work

– Steve Gorvel, Engineering & Facilities Manager at Element Six

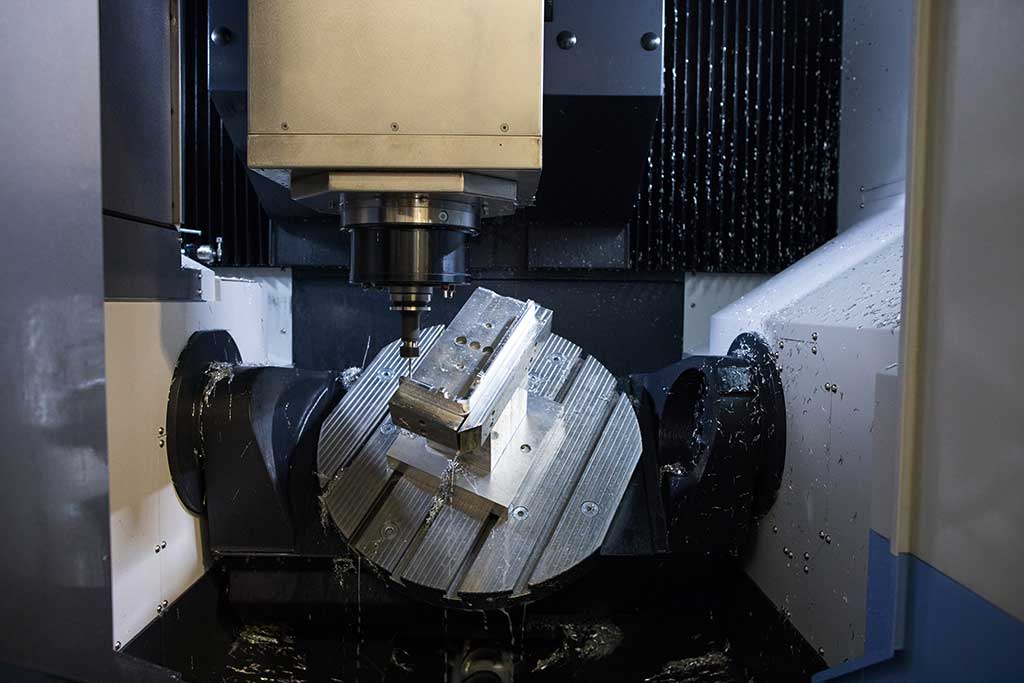

At Lenane Precision Ltd we offer customers high precision machining. From one-off machined parts to medium-volume production, Lenane Precision Ltd has the capacity to machine a wide variety of parts from standard 3 axis to complex 5 axis simultaneous machining.

Using the latest software our machinists are equipped with the right skill set to maximize the 5-axis machines’ capabilities.

5 Axis Machines

Hurco VMX60SRTi

-

Full simultaneous 5-axis machining centre

-

X, Y, Z -axis Travel 1524 x 660 x 610mm

-

Rotary Table Working surface 600ø mm x 500mm High

-

Spindle Speed 12,000RPM

Doosan DVF5000: 2 off

- Full simultaneous 5-axis machining centre

- Maximum Workpiece Envelope: 500mm Ø x 450mm High

- Spindle Speed 12,000RPM

Doosan VC630-5AX

- Full simultaneous 5-axis machining centre

- Maximum Workpiece Envelope: 730ø x 500mm High mm

- Spindle Speed 12,000RPM

Doosan DNM350-5AX

-

X, Y, Z -axis Travel 400 x 655 x 500mm

-

Rotary Table Working surface 350ø mm

-

Spindle Speed 12,000RPM

3 Axis Machines

Doosan VC 3600

- 520mm x 360mm x 465mm

- 12,000 RPM Spindle

- Twin table vertical machining centre

Doosan DNM 5700S

- 1050mm x 570mm x 510mm travel.

- 12,000 RPM Spindle

Doosan DNM 500 II

- 1020mm x 540mm x 510mm Travel,

- 12,000 RPM Spindle

Doosan DNM 400S II

- 762mm x 435mm x 510mm Travel,

- 12,000 RPM Spindle

HURCO VMX30

- 760mm x 508mm x 610mm travel,

- 10,000 RPM Spindle

We use HyperMill & SolidCam to programme our machines, with this we have the ability to take in our customer’s solid model or 2D drawings to instantly create machine programmes which are then downloaded directly on to our machines, this allows us to act and react quicker to our customers’ needs leading to reduced delivery times and on-time deliveries

In a typical scenario we can take your drawing, create a programme and start machining your parts within the hour,

CNC Turning

At Lenane Precision Ltd we can cater for all turning needs ranging up to 300mm diameter, from 1 off to medium-volume production. With sub-spindle, driven tools and bar feeder capabilities we can offer cost effective turned parts, cutting out the need for second operation machining.

Doosan Puma 2600 SY

- Driven Tooling

- Sub Spindle

- Max Turning Ø 360mm

Doosan Puma 220 LSY

- Driven Tooling

- Sub Spindle

- Max Turning Ø 300mm

Doosan Puma 220 LM

- Max Turning Ø 300mm

We have experience in machining all materials from plastics to aluminium to titanium, combining this with the capability of cross drilling or milling directly on the machines ensures accuracy and cuts down on expensive second operations on secondary machines.

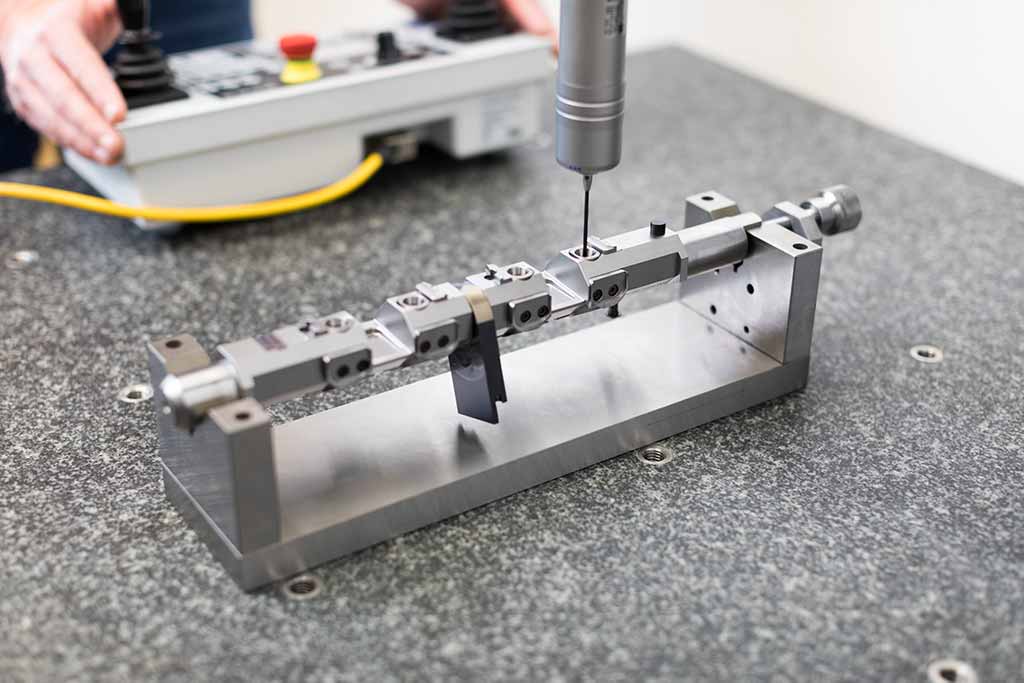

Wire EDM

Our Wire EDM machines can cut any simple or complex 2D shape allowing cut-outs, thin walls, intricate openings and tight radius contours, both internally and externally.

Sodick ALC 400G

- 400mm x 300mm x 250mm

AgieCharmilles AC Progress V2

- 350mm x 250mm x 256mm

Inspection Equipment

Zeiss Contura 3D CMM

Tesa Micro Hite 3D CMM

Design Service

Lenane Precision has been in operation for over 20 years and in that time has built up a huge amount of experience and knowledge in all forms of precision engineering, “we know what works and what doesn’t”. Why not add all that experience to your experience?

With a full seat of Unigraphics NX9 and Solid Works we can help you with all your design ideas.

We can advise on design strategies in relation to cost effective machining. We can take your old 2D drawings and update them to include isometric solid model views for clarity.

We can turn your drawings into solid model assembly animations.

Or, you can discuss your concepts with us and let us create your full design package, From your original idea through the full design stage to prototyping and on to full manufacture, Lenane Precision can assist you to create a final solution.

Services

Surface Grinding

- 2 off Jones & Shipman 540P surface grinders

Milling

- Bridgeport turret milling machine

Turning

- Colchester Triumph 2000

Bead Blasting

- Guyson Bead Blast Cabinet

Project Management

- Anodizing

- Black Oxidizing

- Powder Painting & Various Plating services

- Prototyping

- Complete Manufacturing

- Part Manufacturing

- Design Consultancy

- Inspection

- Validation

- Assembly